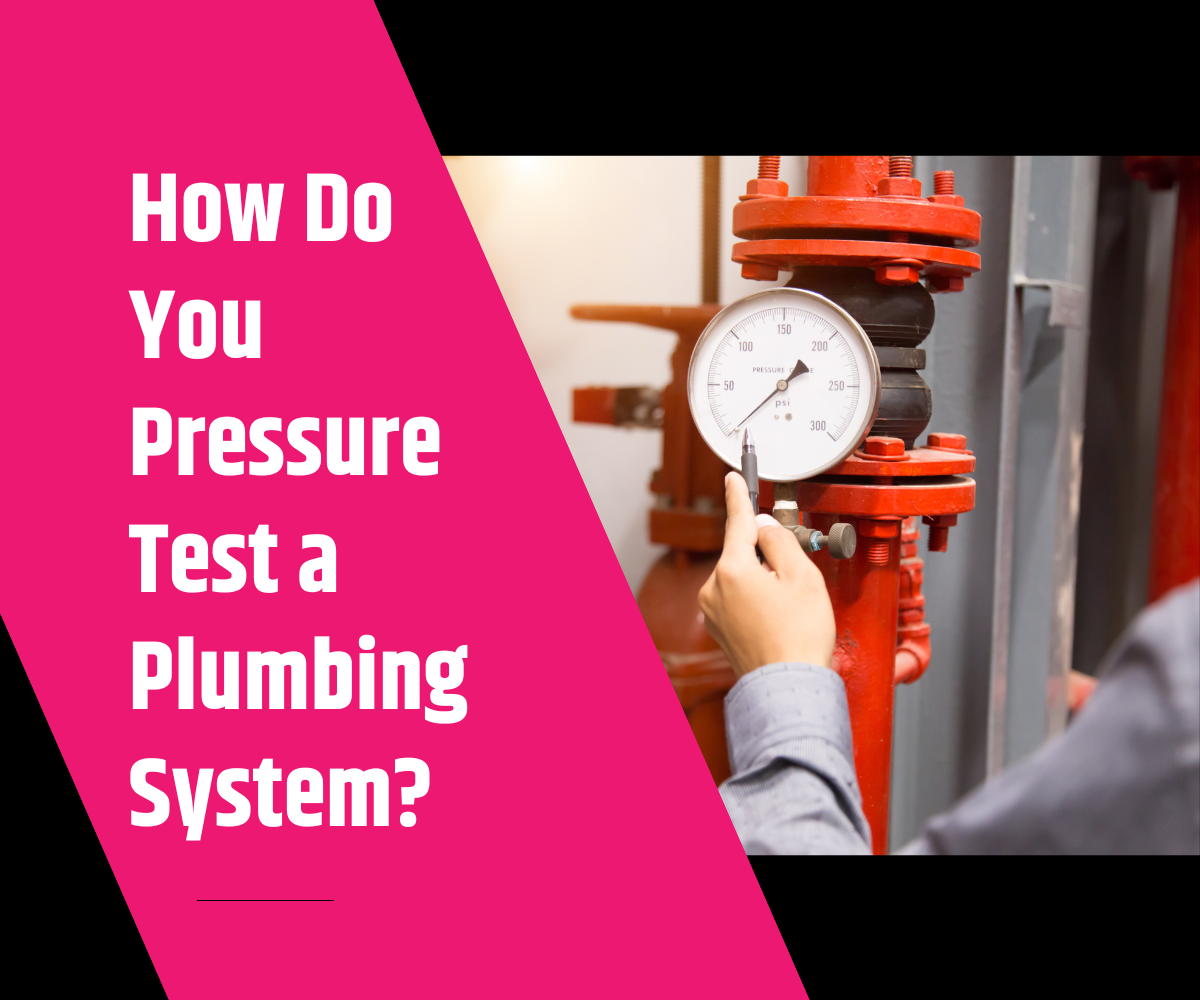

Pressure testing is one of the most important steps in any plumbing project, whether it involves new piping systems, plumbing rough in work, or repairs to existing water lines. Homeowners and contractors often ask, how do you pressure test a plumbing system, especially before walls are closed or fixtures are installed. A proper pressure test confirms that the plumbing system can safely handle working pressure without leaks or failures.

In Washington, pressure testing is commonly required for inspections and permits across Pierce County, King County, Thurston County, and Kitsap County. Pressure testing water lines early helps detect leaks, faulty valves PVC connections, and weak PVC fittings before water damage occurs. Understanding how pressure testing works protects the plumbing system and prevents costly repair issues later.

What Is a Plumbing Pressure Test?

What Does Pressure Testing a Plumbing System Mean?

Pressure testing a plumbing system is a form of leak testing that checks whether pipes, valves PVC components, and PVC fittings can hold pressure over time. The plumbing system is sealed and filled with either air or test water at a controlled level above normal working pressure. A pressure gauge is used to monitor the system during testing.

There are two common pressure testing methods used for plumbing systems:

- Air test

- Water pressure testing

Both methods are used to verify that piping systems are secure and free of leaks before the system is put into service.

When Is a Plumbing Pressure Test Required?

Pressure testing is required in many situations involving plumbing work, including:

- New construction plumbing rough in installations

- Remodels that involve rerouting water lines or replacing pipe sections

- Repairs to piping systems or valves PVC assemblies

- Leak detection verification after repair work

- Code and inspection requirements throughout Washington

Local inspectors often require pressure testing before approving plumbing rough in or final inspections.

How Do You Pressure Test a Plumbing System Step by Step?

Understanding how do you pressure test a plumbing system properly helps ensure safety, compliance, and long term performance.

Step 1: Shut Off the Water Supply

The first step in pressure testing is isolating the plumbing system by shutting off the main water supply. This prevents additional water from entering the system and interfering with accurate pressure testing results.

Step 2: Cap All Open Plumbing Lines

All open water lines, fixture connections, and pipe ends must be sealed using test caps or plugs. Properly sealing water lines ensures the pressure test accurately reflects the condition of the plumbing system.

Step 3: Connect the Pressure Testing Gauge

A pressure gauge is connected to the plumbing system at an accessible location. This gauge measures pressure during testing and helps detect pressure loss that may indicate leaks in piping systems, valves PVC connections, or PVC fittings.

Step 4: Add Pressure to the Plumbing System

Pressure is introduced into the system using either compressed air or test water. The system is slowly brought up to the required working pressure to avoid damaging pipes or fittings. Air test methods and water pressure testing are both used depending on project conditions.

Step 5: Monitor the Pressure Over Time

Once pressure is reached, the system is monitored for a specific testing period. A stable pressure reading means the plumbing system is holding pressure. Any pressure drop indicates potential leaks or weak connections within the piping systems.

Step 6: Inspect for Leaks

Visible leaks, moisture, or pressure loss may signal issues within the plumbing system. Leak detection during pressure testing helps identify problems before walls, floors, or slabs are closed.

How Do You Pressure Test a Plumbing System for a Rough In Inspection in Washington?

What PSI Is Used for Rough In Plumbing Pressure Tests?

For plumbing rough in inspections, pressure testing typically requires the system to be pressurized above normal water pressure. The exact PSI depends on local codes and system design, but the pressure must remain stable to pass inspection.

How Long Does a Rough In Pressure Test Need to Hold?

During inspection, the pressure test must hold steady for the required testing period. Inspectors look for:

- Consistent pressure readings

- Secure pipe connections

- No signs of leaks

How Do You Pressure Test a Plumbing System Using Air vs Water?

Air Pressure Testing Pros and Cons

Air test methods are often used when water is not available.

- Reduced risk of water damage

- Faster setup in early construction

- Requires careful handling due to compressed air hazards

Water Pressure Testing Pros and Cons

Water based pressure testing uses test water to fill the system.

- Closely simulates real operating conditions

- Easier leak detection

- Risk of water damage if leaks are present

What Are the Signs a Plumbing System Fails a Pressure Test?

Common Signs of Pressure Loss

- Pressure gauge readings drop during testing

- Audible air escaping during an air test

- Visible water leaks during water pressure testing

Hidden Leak Warning Signs

- Pressure drops without visible water

- Moisture behind walls or under slabs

- Structural damage risks to the plumbing system

How Much Does It Cost to Pressure Test a Plumbing System in Washington?

Average Plumbing Pressure Test Cost in Pierce, King, Thurston, and Kitsap Counties

The cost of pressure testing depends on:

- Size of the plumbing system

- Accessibility of piping systems

- Type of pressure testing required

- Coordination with inspections

Is Pressure Testing Included in Plumbing Inspections?

Pressure testing may be:

- Included with permitted plumbing work

- Billed separately for leak detection or verification

- Required again after repair or system changes

Can You Pressure Test a Plumbing System Yourself?

DIY Plumbing Pressure Testing Risks

- Incorrect pressure levels

- Equipment misuse

- Inaccurate leak detection

- Damage to PVC fittings or valves PVC components

When DIY Pressure Testing Is Not Recommended

- Remodels involving permits

- Older plumbing systems

- Plumbing rough in projects

- Complex piping systems

Why Choose a Professional Plumber to Pressure Test a Plumbing System?

Benefits of Hiring a Licensed Washington Plumber

- Accurate pressure testing results

- Compliance with local plumbing codes

- Reduced risk of system damage

- Inspection ready documentation

How Professional Pressure Testing Saves Money Long Term

- Prevents hidden leaks

- Avoids failed inspections

- Reduces future repair costs

How Do You Pressure Test a Plumbing System During Remodeling Projects?

Pressure Testing Before Drywall Installation

Pressure testing before drywall ensures leaks are found early and prevents damage to finished surfaces.

Pressure Testing After Plumbing Repairs or Repiping

After repair or repiping, pressure testing confirms all water lines, piping systems, and fittings are secure and operating correctly.

Plumbing Pressure Testing Requirements in Washington State

Local Plumbing Code Considerations

Washington plumbing codes require pressure testing to verify system integrity. Inspectors expect:

- Proper working pressure levels

- Correct testing duration

- Secure system sealing

Why Code Compliant Pressure Testing Matters

- Required for permits

- Important for home resale

- Impacts insurance coverage

Areas We Serve in Washington

Bowers Plumbing & Remodel provides plumbing pressure testing, leak detection, and repair services throughout:

- Pierce County

- King County

- Thurston County

- Kitsap County

Service areas include Tacoma, Puyallup, Lakewood, Seattle, Bellevue, Kent, Olympia, Lacey, Tumwater, Bremerton, Silverdale, and surrounding communities.

Why Homeowners Choose Bowers Plumbing & Remodel

Local Experience With Washington Plumbing Systems

Our team has extensive experience working with residential plumbing systems, piping systems, and remodel projects across Washington.

Trusted Plumbing Services Across Multiple Counties

- Licensed professionals

- Insured services

- Inspection ready plumbing work

Schedule a Plumbing Pressure Test With Bowers Plumbing & Remodel

Bowers Plumbing & Remodel provides professional pressure testing, leak detection, and repair services for residential plumbing systems across Washington. Our team ensures plumbing systems meet inspection standards and operate safely at proper water pressure.

We serve Pierce, King, Thurston, and Kitsap Counties with reliable plumbing solutions for remodels, repairs, and new construction projects. Contact Bowers Plumbing & Remodel today to schedule pressure testing for your plumbing system.

Phone: (253) 453-5789

Frequently Asked Questions About Plumbing Pressure Testing

How do you pressure test a plumbing system safely?

By sealing all water lines, applying controlled pressure, monitoring readings, and performing leak detection during testing.

How long should a plumbing pressure test hold?

The pressure test must hold steady for the required testing period specified by local inspection requirements.

What happens if a plumbing system fails a pressure test?

Leaks must be located, repaired, and the system must be retested before approval.

Is pressure testing required before inspection in Washington?

Yes. Pressure testing is commonly required before plumbing rough in and final inspections.